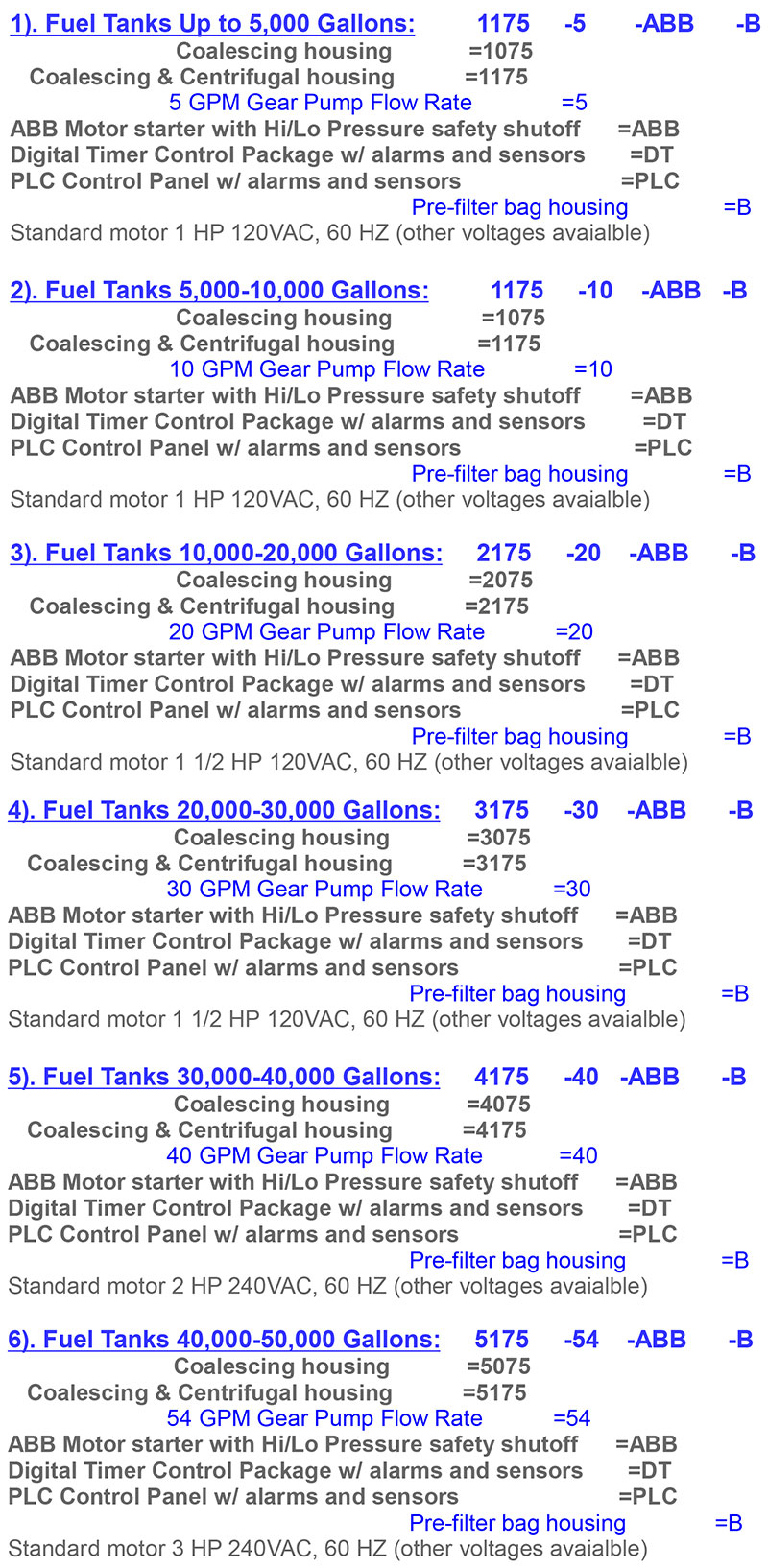

| Stationary Fuel Polishing Machines | Download Brochure |

Perfect Filtration Systems Portable Fuel Polishing machines are offered in two different filtration processes.

Model 1075-4075’s use Ultimate Coalescing Fuel / Water Separator housing

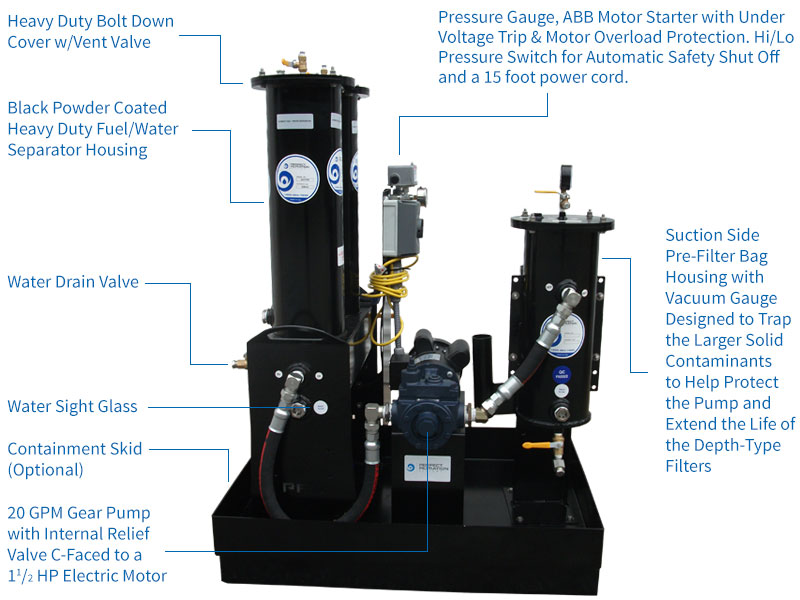

Step 1 Coalescing chamber: The fuel enters the filter housing and is forced down into the coalescing chamber where the fuel flows through very fine stainless steel mesh material where the small water droplets come together (Coalesce) as the fuel flows through the small opening in the mesh material. The heavier water droplets drop out of the fuel flow and settle to the bottom to be drained off. Water sight glasses are present to view the presence of water and a drain valve in also provided.

Step 2 Depth-type filter chamber: After the fuel exits the coalescing chamber it enter the filtration chamber, the 3-micron cellulose depth-type filter traps the majority of the solids particulates including: dirt, metal, bacteria, algae, microbes, and other solid contaminants. The filter also has water absorbing capabilities to remove free and emulsified water that was not removed in the first two steps. The depth-type filter has a very large water and contaminate holding capacity which means long filter life and high efficiency. Each filter can absorb up to 1 gallon of water and can hold 8-10 lbs of solids. Once the fuel is filtered it exists the filter housing through a stainless steel pipe ultra clean.

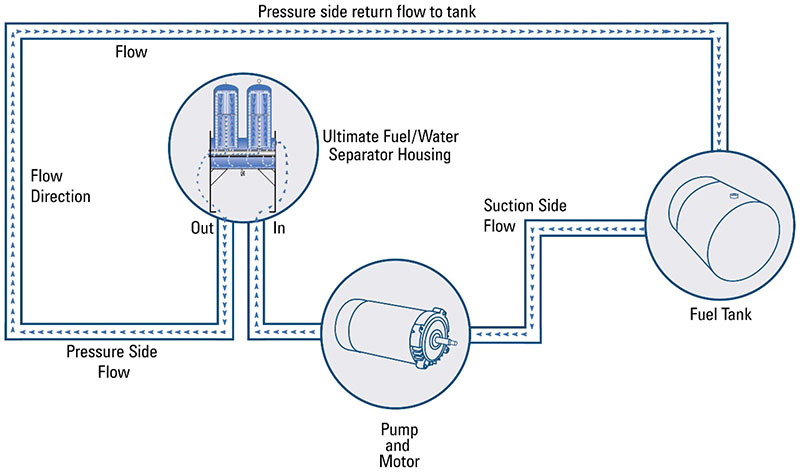

Model 1175-4175’s use Ultimate Coalescing & Centrifugal Fuel / Water Separator housing

Step 1 Coalescing chamber: The fuel enters the filter housing and is forced down into the coalescing chamber where the fuel flows through very fine stainless steel mesh material where the small water droplets come together (Coalesce) as the fuel flows through the small opening in the mesh material. The heavier water droplets drop out of the fuel flow and settle to the bottom to be drained off. Water sight glasses are present to view the presence of water and a drain valve in also provided.

Step 2 Centrifugal chamber: This process occurs when the fuel exits the coalescing chamber and flows upward into the centrifugal chamber. The fuel flows through a stainless steel pipe and comes in direct contact with a stainless steel coned baffle spinning the fuel in a circular motion (Centrifugal force). This motion causes the heavier water droplets to fall out of the fuel flow to be drained off. Water sight glasses are present to view the presence of water and a drain valve in also provided.

Step 3 Depth-type filter chamber: After the fuel exits the centrifugal chamber it enter the filtration chamber, the 3-micron cellulose depth-type filter traps the majority of the solids particulates including: dirt, metal, bacteria, algae, microbes, and other solid contaminants. The filter also has water absorbing capabilities to remove free and emulsified water that was not removed in the first two steps. The depth-type filter has a very large water and contaminate holding capacity which means long filter life and high efficiency. Each filter can absorb up to 1 gallon of water and can hold 8-10 lbs of solids. Once the fuel is filtered it exists the filter housing through a stainless steel pipe ultra clean.

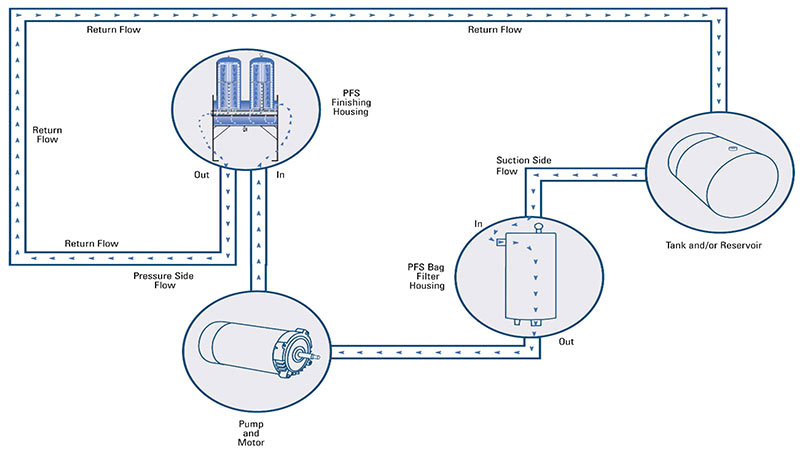

Pre-filter bag housing are available with all models to help protect the pump and extend filter element life

| Coalescing Water Separation | Model 1075-5-ABB | Model 1075-10-ABB | Model 2075-20-ABB | Model 3075-30-ABB | Model 4075-40-ABB | Model 5075-54-ABB |

|---|---|---|---|---|---|---|

| Coalescing & Centrifugal Water Separation | Model 1175-5-ABB | Model 1175-10-ABB | Model 2175-20-ABB | Model 3175-30-ABB | Model 4175-40-ABB | Model 5175-54-ABB |

| Standard Gear Pump | 5 GPM | 10 GPM | 20 GPM | 30 GPM | 40 GPM | 54 GPM |

| Motor Horse Power | 1 HP | 1 HP | 1.5 HP | 1.5 HP | 2 HP | 3 HP |

| Standard Motor Voltages | 120VAC, 1 phase, 60HZ | 120VAC, 1 phase, 60HZ | 120VAC, 1 phase, 60HZ | 120VAC, 1 phase, 60HZ | 240VAC, 1 phase, 60HZ | 240VAC, 1 phase, 60HZ |

| Available Voltages | 240, 1 phase 50/60 hz, or 240/480, 3 phase, 50/60 hz, or Explosion Proof or Pneumatic | |||||

| Standard ABB Motor Starter & Squre D Hi/lo Pressure Switch | Included | Included | Included | Included | Included | Included |

| Width | 12″ | 12″ | 12″ | 12″ | 12″ | 12″ |

| Height | 55″ | 55″ | 55″ | 55″ | 55″ | 55″ |

| Length | 40″ | 40″ | 48″ | 60″ | 88″ | 105″ |

| Dry Weight | 175 lbs | 175 lbs | 275 lbs | 375 lbs | 600 lbs | 700 lbs |

| Water Sight Glasses | Included | Included | Included | Included | Included | Included |

| Standard Water Drain | 1/2″ NPT | 1/2″ NPT | 1/2″ NPT | 1/2″ NPT | 1/2″ NPT | 1/2″ NPT |

| Fuel Replacement Element | #3914 | #3914 | #3914 | #3914 | #3914 | #3914 |

| Number of 3914 Filter Required | 1 | 1 | 2 | – | – | – |

| Element Dimensions | 7.5″ x 19.75″ | 7.5″ x 19.75″ | 7.5″ x 19.75″ | 7.5″ x 19.75″ | 7.5″ x 19.75″ | 7.5″ x 19.75″ |

| Element Micron Rating | 3 Micron | 3 Micron | 3 Micron | 3 Micron | 3 Micron | 3 Micron |

| Filter Performance per ISO 16889 | B3<(c)=1000 | B3<(c)=1000 | B3<(c)=1000 | B3<(c)=1000 | B3<(c)=1000 | B3<(c)=1000 |

| Filter Solid Holding Capacity | 8 to 10 lbs | 8 to 10 lbs each | 8 to 10 lbs each | 8 to 10 lbs each | 8 to 10 lbs each | 8 to 10 lbs each |

| Filter Water Holding Capacity | 1 gal. | 1 gal. | 2 gal. | 3 gal. | 4 gal. | 5 gal. |

| Water Removal Efficiency | 99.90% | 99.90% | 99.90% | 99.90% | 99.90% | 99.90% |

Optional Items |

||||||

| 5-Micron Pre-Filter Bag Housing | Suffix-B | Suffix-B | Suffix-B | Suffix-B | Suffix-B | Suffix-B |

| Number of Bag Housings Required | – | – | – | – | – | – |

| Digital Timer Control Package | Suffix-DT | Suffix-DT | Suffix-DT | Suffix-DT | Suffix-DT | Suffix-DT |

| PLC Control Package | Suffix-PLC | Suffix-PLC | Suffix-PLC | Suffix-PLC | Suffix-PLC | Suffix-PLC |

Smaller and larger systems are available.

Depth-type filtration is known to be the most efficient filtering technique. Great product for fuel cleanliness and price value.