| ABS Approved Ultimate Fuel Water Separators | Download Brochure |

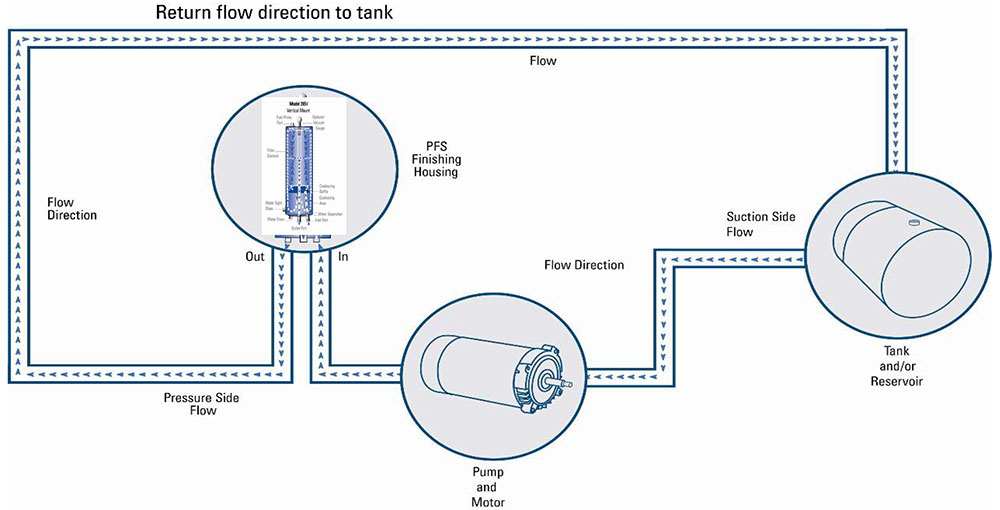

The Ultimate Centrifugal Fuel/water Separators can be installed on the pressure side and/or the suction side of the existing dispensing fuel pump and are sized based on the flow rate of the pump. This schematic shows pressure side application.

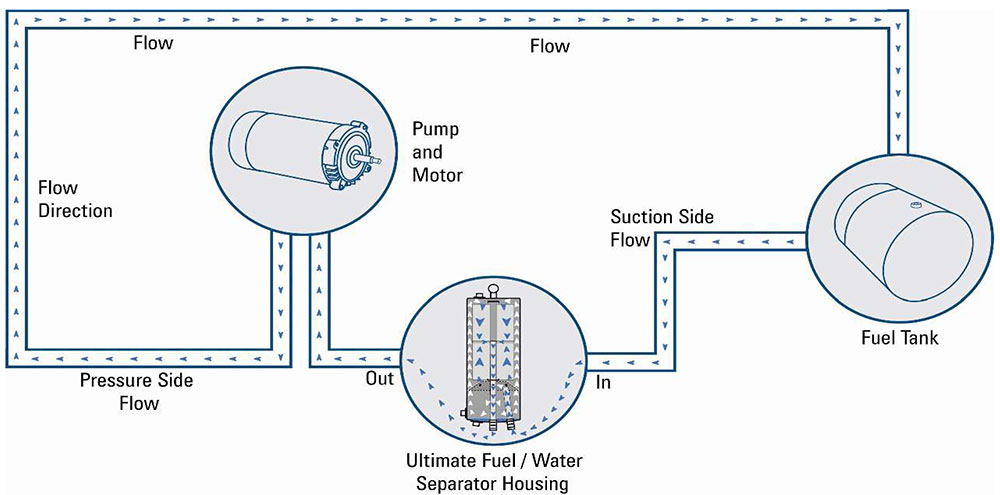

This schematic shows suction side application.

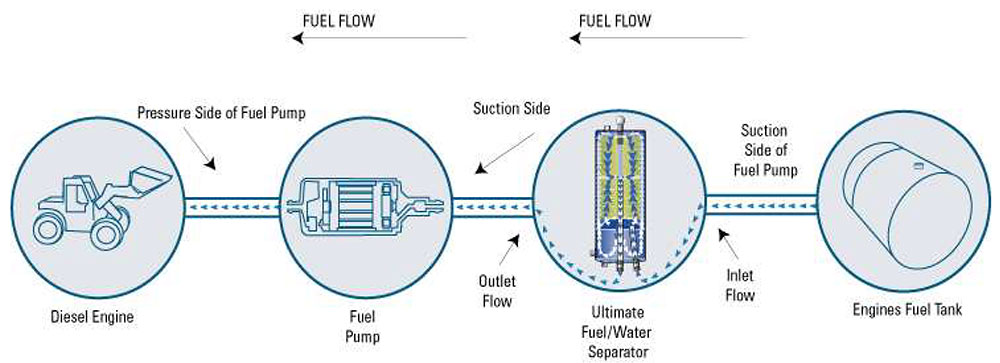

The Ultimate Fuel / Water Separators installed on the suction side of the existing fuel pump and becomes the primary fuel filter.

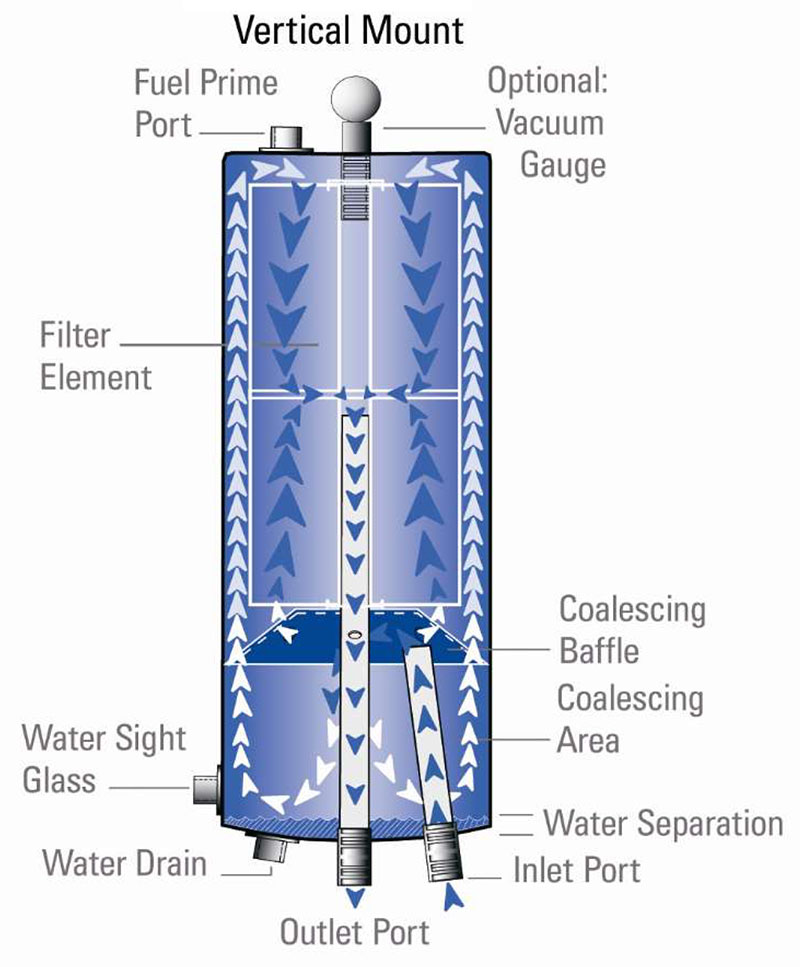

Ultimate Fuel / Water Separators available in Carbon Steel and/or 304 Stainless Steel heavy duty housings. All housings have bolt down covers to make is easy to service the filter element. Systems can be installed on the suction side or pressure side of an existing fuel pump. Pump and motor systems are also available. Large variety of sizes and flow rates to handle low volume or high volumes of fuel. Manifolded piping systems can be assembled to operate independently or in parallel.

| Model | 280V | 290V | 295V | 975V | 280V-DMP | 290V-DMP | 295V-DMP | 975V-DMP |

|---|---|---|---|---|---|---|---|---|

| Width | 9″ | 11″ | 11″ | 11″ | 24″ | 28″ | 28″ | 28″ |

| Height | 18″ | 24″ | 28″ | 24″ | 34″ | 30″ | 34″ | 30″ |

| Approx. Dry Weight | 35 lbs. | 55 lbs. | 65 lbs. | 55 lbs. | 130 lbs. | 150 lbs. | 170 lbs. | 150 lbs. |

| Inlet & Outlet | 3/4″ NPT | 3/4″ NPT | 3/4″ NPT | 3/4″ NPT | 3/4″ NPT | 3/4″ NPT | 3/4″ NPT | 3/4″ NPT |

| Engine Cylinders | 2-6 cylinders | 12-16 cylinders | 12-16 cylinders | 12-16 cylinders | 2-6 cylinders | 12-16 cylinders | 12-16 cylinders | 12-16 cylinders |

| Max. Flow Rate | 30 GPH, 1,135 LPH | 720 GPH, 2,725 LPH | 900 GPH, 3,406 LPH | 900 GPH, 3,406 LPH | 600 GPH, 2,725 LPH | 1,440 GPH, 5,451 LPH | 1800 GPH, 6,813 LPH | 1800 GPH, 6,813 LPH |

| Max. Pressure | 80 psi | 80 psi | 80 psi | 80 psi | 80 psi | 80 psi | 80 psi | 80 psi |

| Max. Vacuum | 29.9 IN HG | 29.9 IN HG | 29.9 IN HG | 29.9 IN HG | 29.9 IN HG | 29.9 IN HG | 29.9 IN HG | 29.9 IN HG |

| Filter Water Absorption | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Centrifugal Water Separation | Yes | Yes | Yes | No | Yes | Yes | Yes | No |

| Pressure Side or Vacuum Side Install | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Drain Valve, Sight Glass & Gauge | Included | Included | Included | Included | Included | Included | Included | Drain Valve & Gauge |

| Filter Dimensions | 5″ x 8 /2″” | 7″ x 15″ | 7″ x 19.75″ | 7″ x 19.75″ | 7″ x 10″ | 7″ x 15″ | 7″ x 19.75″ | 7″ x 19.75″ |

| Element Water and Solid Holding Capacity Each | 1 Qt. Water, 1 lb. Solids | 3/4 Gal. Water, 7-8 lbs. solids | 1 Gal. Water, 8-10 lbs. solids | 1 Gal. Water, 8-10 lbs. solids | 1 Qt. Water, 1 lb. solids | 3/4 Gal. Water, 7-8 lbs. solids | 1 Gal. Water, 8-10 lbs. solids | 1 Gal. Water, 8-10 lbs. solids |

| Filter # Micron Rating & Filter Performance | #7132 3-micron, B3<(c)=200 | #7432 3-micron, B3<(c)=200 | #3914 3-micron, B3<(c)=150 | #3914 3-micron, B3<(c)=150 | #7132 3-micron, B3<(c)=200 | #7432 3-micron, B3<(c)=200 | #3914 3-micron, B3<(c)=150 | #3914 3-micron, B3<(c)=150 |

| Filter # Micron Rating & Filter Performance | N/A | #7434 7-micron, B7<(c)=200 | #3916 7-micron, B7<(c)=200 | #3916 7-micron, B7<(c)=200 | N/A | #7434 7-micron, B7<(c)=200 | #3916 7-micron, B7<(c)=200 | #3916 7-micron, B7<(c)=200 |

| Filter # Micron Rating & Filter Performance | #7134 15-micron, B15<(c)=200 | N/A | #3918 15-micron, B15<(c)=200 | #3918 15-micron, B15<(c)=200 | #7134 15-micron, B15<(c)=200 | N/A | #3918 15-micron, B15<(c)=200 | #3918 15-micron, B15<(c)=200 |

| DMP models can operate in parallel or in series |

Suffix Descriptions

V=Vertical Mounting

DMS=Manifold piping and valving independently (Fuel flows through one housing while the other is in stand-by)

DMP=Manifold piping and valving in parallel (Fuel flows through both housings at the same time)

SS=304 Stainless steel housing or CS=Carbon steel housing (black or white powder coated)

Used dirty fuel filters full of dirt, bacteria, algae, water, microbes, and other solid contaminants.

What you can expect after installing the product

10 year product warranty. Best in the industry.