| Bypass Kidney Loop Systems | Download Brochure |

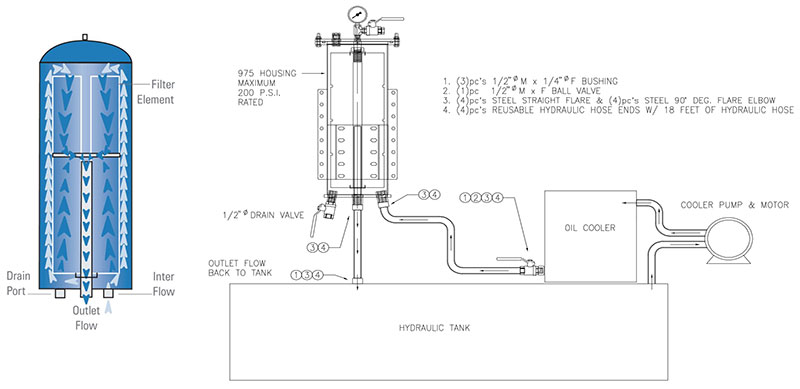

The filtration process is designed to use a low pressure source (15psi min -150psi max.) like a recirculating cooler or other pumps that do not generate pressures above 150 psi. The low pressure source pushes the hydraulic fluid into the filter housing where the 3-micron depth-type filter element absorbs free and emulsified water and traps solid particles. Once the fluid is filtered it exits the housing and is returned back into the tank. If the pressures are over 150 psi consult PFS for special flow control valves and relief valves.

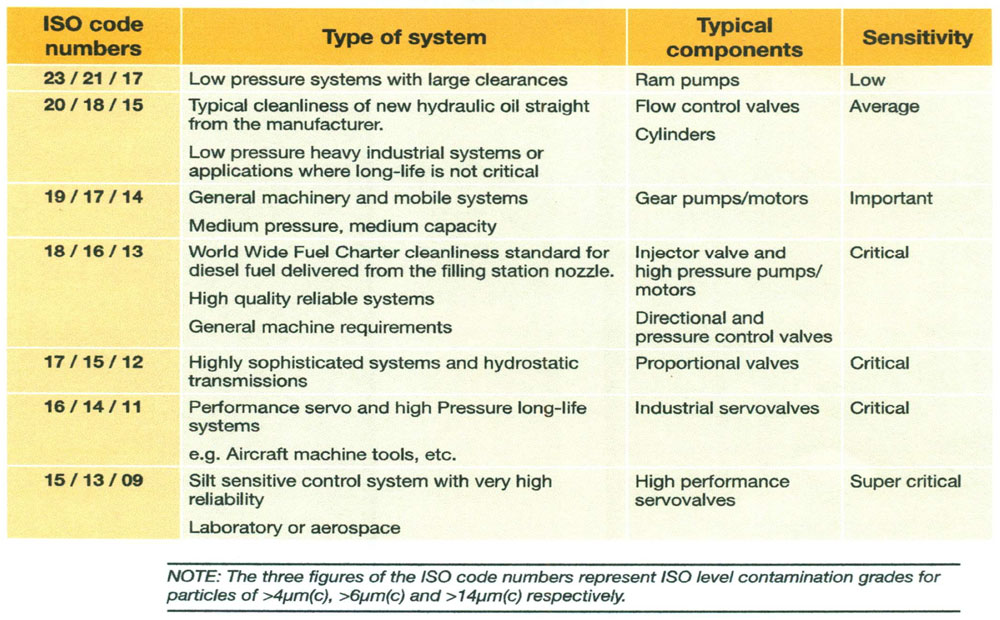

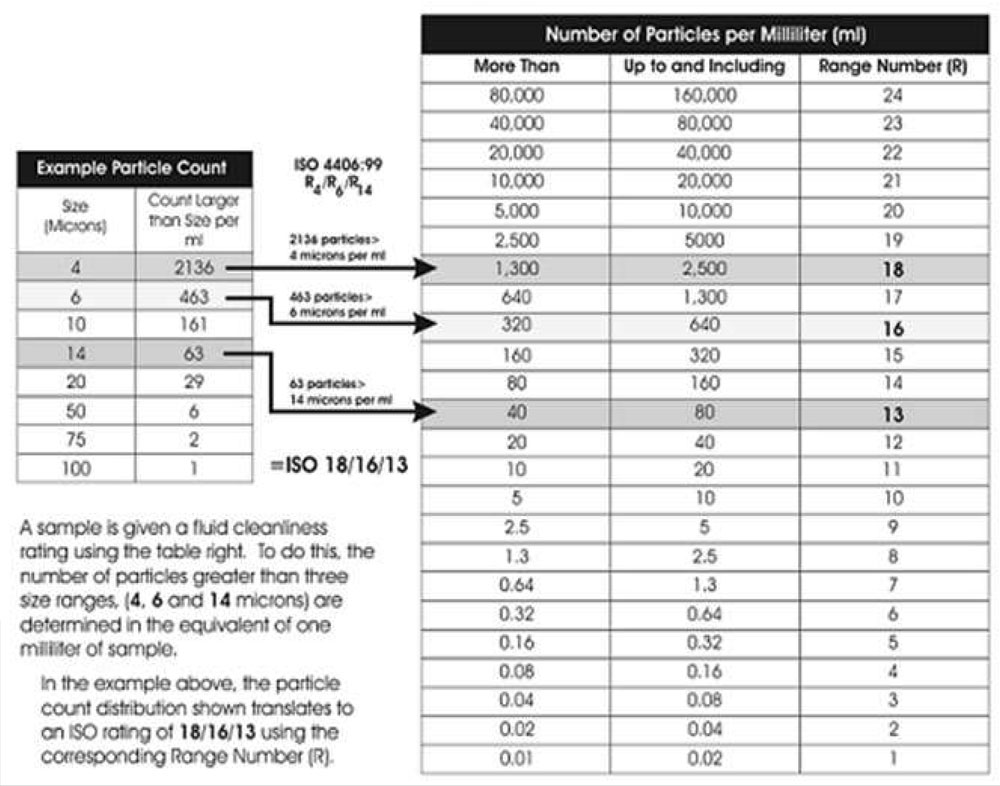

PFS Guarantees after 200 hours of filtration the hydraulic fluid will be cleaner than brand new hydraulic oil.

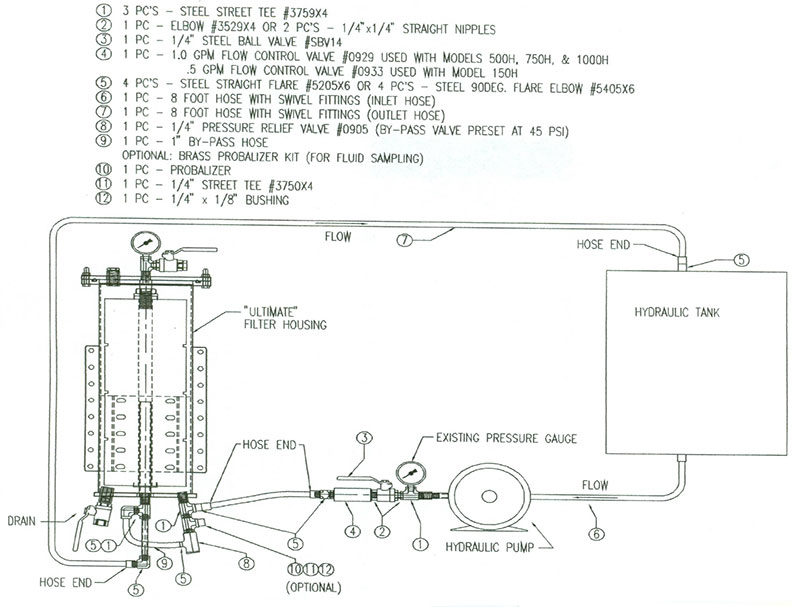

The filtration process is designed to use a high pressure source (50 psi min – 3,000psi max.) Tee into the high pressure line and install a steel shutooff ball valve to isolate the filter housing when a filter service is required and then install a flow control valve (.5 gpm -2.0 gpm) to reduce the pressure down to 5 psi- 50 psi. The low volume low pressure hydraulic fluid will flow into the filter housing where the 3-micron depth-type filter element absorbs free and emulsified water and traps solid particles. Once the fluid is filtered it exits the housing and is returned back into the tank.

PFS Guarantees after 200 hours of filtration the hydraulic fluid will be cleaner than brand new hydraulic oil.

All heavy duty housings are made of carbon steel with a black powder coated finish inside and out with all stainless internal wetted parts. The industrial strength housings use a bolt down cover to ensure a rugged positive seal.

Best housing warranty in the industry. 10 years.

| Model | U-150H | U-500H | U-1000H | U-2-1000H |

|---|---|---|---|---|

| Housing Diameter | 6″ | 8″ | 8″ | 8″ |

| Bracket Width | 8″ | 10.75″ | 12″ | 24″ |

| Length | 14″ | 14″ | 24″ | 24″ |

| System Dry Weight | 28 lbs. | 36 lbs. | 50 lbs. | 100 lbs. |

| Reservoir Sizing Recommendations | up to 40 gal. | 40-100 gal. | 100-300 gal. | 300-600 gal. |

| Flow Control Valve | .25 gpm | .5 gpm | 1.0 gpm | 2.0 gpm |

| Maximum Housing Pressure | 150 psi | 150 psi | 150 psi | 150 psi |

| Maximum System Pressure | 3,000 psi | 3,000 psi | 3,000 psi | 3,000 psi |

| Make Up Fluid Required | 4 qts. | 12 qts. | 20 qts. | 40 qts. |

| Standard Inlet and Outlet Ports | .25″ NPT | .25″ NPT | .25″ NPT | .25″ NPT |

| Standard Fluid Drain | .5″ NPT | .5″ NPT | .5″ NPT | .5″ NPT |

| Replacement O-ring | 318 | 433 | 433 | 433 |

| Pressure Gauge | Optional | Optional | Optional | Optional |

| Relief valve (High pressure) | Included | Included | Included | Included |

| Water Removal Efficiency | 99.90″ | 99.90″ | 99.90″ | 99.90″ |

| Hydraulic Filter Element | 7132 | 7332 | 7534 | (2)-7534 |

| Element Dimensions | 5″ x 8 13/16″ | 7″ x 10″ | 7″ x 19 3/4″ | 7″ x 19 3/4″ |

| Element Micron Rating | 3 Micron | 3 Micron | 3 Micron | 3 Micron |

| Beta Rating | B3<(c)=200 | B3<(c)=200 | B3<(c)=150 | B3<(c)=150 |

| Element Water Holding Capacity | 1 qt. | .5 gal. | 1 gal. | 1 gal. each |

| Element Water Holding Capacity | 2 -3 lbs. | 4-5 lbs. | 8-10 lbs. | 8-10 lbs. each |

| Number of Elements Required | 1 | 1 | 1 | 2 |

For larger systems go to stationary recirculating systems or contact us.

Model U-150H-LP = Up to 40 gallons

Model U-500H-LP = 40–100 gallons

Model U-2-500H-LP = 200-400 gallons

Model U-1000H-LP = 100-300 gallons

Model U-2-1000H-LP = 300-600 gallons

Model U-150H-PRV = Up to 40 gallons

Model U-500H-PRV = 40–100 gallons

Model U-2-500H-PRV = 200-400 gallons

Model U-1000H-PRV = 100-300 gallons

Model U-2-1000H-PRV = 300-600 gallons

All PRV kits include: housing, bracket, filter, 18 foot hose with hose ends, gauge, by-pass relief valve with by-pass hose, steel shut off ball valve, flow control valve, and JIC fittings.

For larger tanks contact us for additional options.